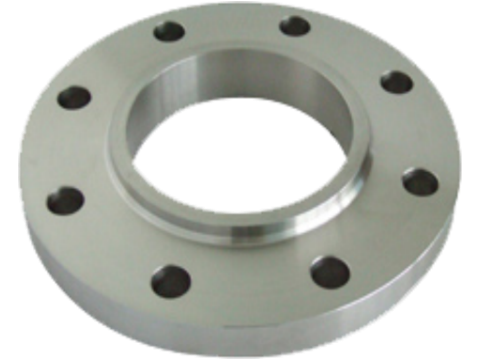

Slip On Flange

Slip On Flange

Place two fillets by welding, sliding inside the tube. So its installation cost is lower, requiring less precision in cutting the pipe| Size Heading | Pressure | Dimensional Standard |

|---|---|---|

| 1/2”To 48” | 150# | ANSI/ASMEB16.5 |

| 1/2”To 48” | 300# | ASMEB16.47 |

| 1/2”To 24” | 400# | SR.A |

| 1/2”To 30” | 600# | SR.B |

| 1/2”To 24” | 900# | MSSSP44 |

| 1/2”To 12” | 1500# | BS3293 |

| 1/2”To 08” | 2500# | BS4504 /DIN |

Welding Neck

WELDING NECK

They join the buttwelded pipe. They are preferred when radio graphed joints is required, or when e fforts are highest on the union. The long conical neck optimazis stress distribution.| Size Heading | Pressure | Dimensional Standard |

|---|---|---|

| 1/2”To 48” | 150# | ANSI/ASMEB16.5 |

| 1/2”To 48” | 300# | ASMEB16.47 |

| 1/2”To 24” | 400# | SR.A |

| 1/2”To 30” | 600# | SR.B |

| 1/2”To 24” | 900# | MSSSP44 |

| 1/2”To 12” | 1500# | BS3293 |

| 1/2”To 08” | 2500# | BS4504 /DIN |

Blind Flange

Blind Flange

Developed especially for small diameters and high pressures. Tube is inserted in them to the seat and then is welded in against the cube steak.| Size Heading | Pressure | Dimensional Standard |

|---|---|---|

| 1/2”To 24” | 150# | ANSI/ASMEB16.5 |

| 1/2”To 24” | 300# | ASMEB16.47 |

| 1/2”To 24” | 400# | SR.A |

| 1/2”To 24” | 600# | SR.B |

| 1/2”To 24” | 900# | MSSSP44 |

| 1/2”To 12” | 1500# | BS3293 |

Threaded Flange

Threaded Flange

They are placed in pre-threaded pipe, usually in places where welding cannot be applied. Not recommended for use in systems with intense pressure variations.| Size Heading | Pressure | Dimensional Standard |

|---|---|---|

| 1/2”To 24” | 150# | ANSI/ASMEB16.5BS4504 / DIN |

| 1/2”To 24” | 300# | |

| 1/2”To 24” | 400# | |

| 1/2”To 24” | 600# | |

| 1/2”To 24” | 900# | |

| 1/2”To 12” | 1500# | |

| 1/2”To 08” | 2500# |

Lap Joint Flange

https://adityaforge.com/wp-content/uploads/2016/04/40_Flanges_623.gifLap Joint Flange

Overlapping sliding on a board. Usually used in places where it is often necessary to disassemble for cleaning or dismantling reparaciones.El cost decreases because of the ease of turning the flanges and align the holes.| Size Heading | Pressure | Dimensional Standard |

|---|---|---|

| 1/2”To 24” | 150# | ANSI/ASMEB16.5 BS4504 / DIN |

| 1/2”To 24” | 300# | |

| 1/2”To 24” | 400# | |

| 1/2”To 24” | 600# | |

| 1/2”To 24” | 900# | |

| 1/2”To 12” | 1500# | |

| 1/2”To 08” | 2500# |

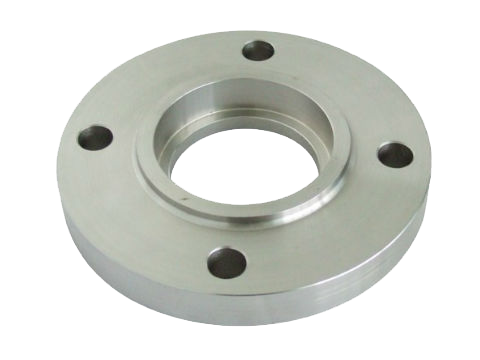

Socket Welding

Socket Welding

Developed especially for small diameters and high pressures. Tube is inserted in them to the seat and then is welded in against the cube steak.| Size Heading | Pressure | Dimensional Standard |

|---|---|---|

| 1/2”To 4” | 150# | ANSI/ASMEB16.5 |

| 1/2”To 4” | 300# | |

| 1/2”To 4” | 400# | |

| 1/2”To 4” | 600# | |

| 1/2”To 4” | 900# | |

| 1/2”To 4” | 1500# | |

| 1/2”To 4” | 2500# |